News Center

Recommending Products

Contact: Mr. Jin

Tel: 13901575780

0512-52428686

Contact: Mr. Zha

Tel: 13913639797

0512-52422071

Address: No. 59, Huyi Road, Liantang, Shanghu Town, Changshu City, Jiangsu Province.

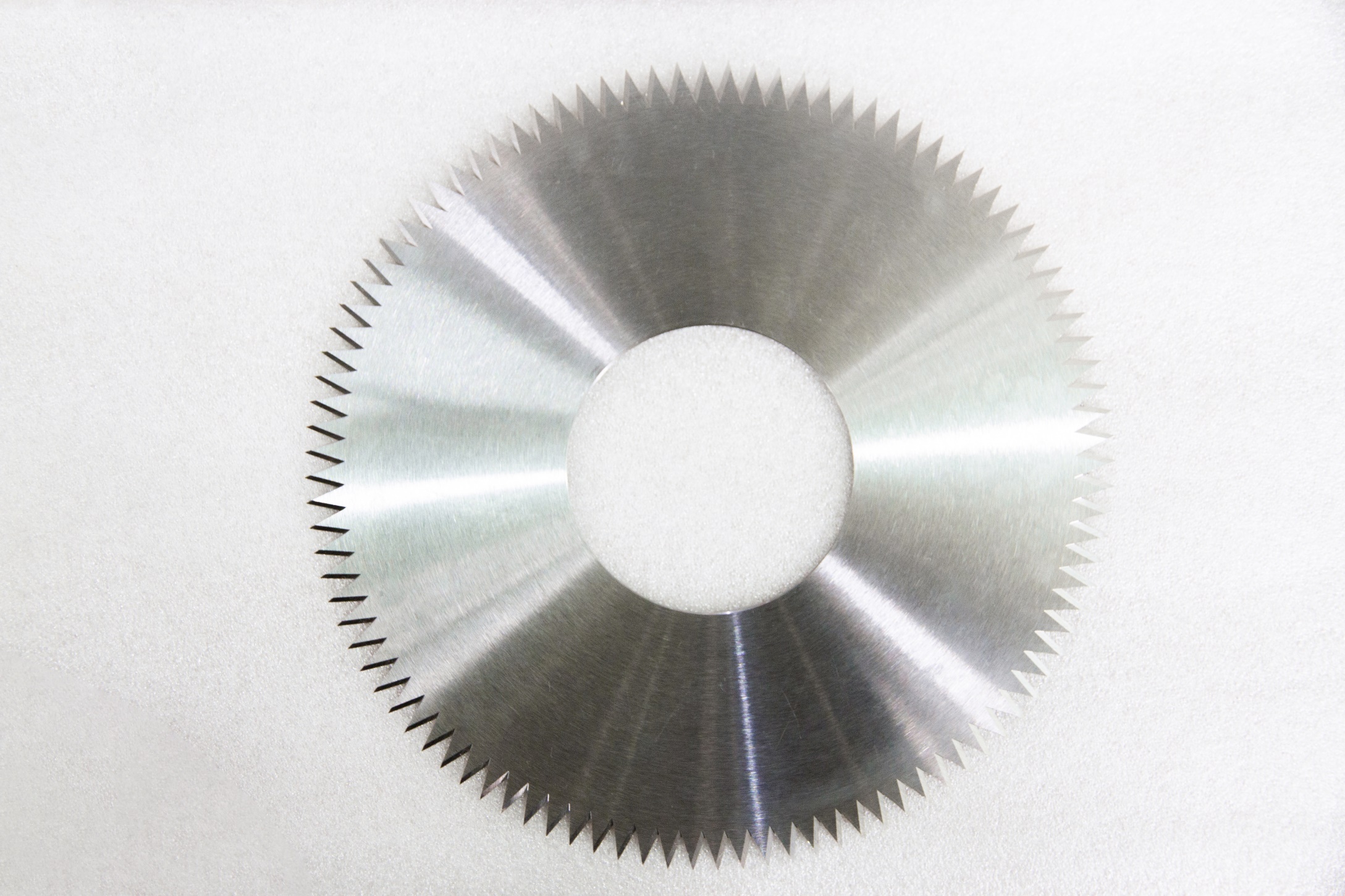

What is the function of high-speed steel sharp angle knife

High speed steel sharp angle cutter is a type of cutting tool made of High Speed Steel (HSS) material and designed with a sharp angle blade. Its unique material characteristics and geometric shape give it a clear functional positioning in the field of mechanical processing. Its main functions are as follows:Sources:www.bsztq.com.cn | PublishDate:2025.06.24

1、 Material and structural characteristics

Advantages of high-speed steel materials: containing alloy elements such as tungsten, molybdenum, chromium, and vanadium, it has high hardness (62-67HRC), high wear resistance, and good thermal hardening (can still maintain cutting performance at around 600 ℃), suitable for processing various metal materials such as cast iron, carbon steel, and alloy steel.

Sharp angle design features: The blade angle is usually less than 90 ° (such as 45 °, 30 °, etc.), the blade tip is sharp and the edge strength is high, which can correctly cut into the workpiece and form a narrow cutting path.

2、 Core role

1. Precision machining and chamfering

Narrow space chamfering: Chamfering is performed in narrow areas such as grooves, holes, and edges of parts (such as 45 ° chamfering) to remove burrs and form smooth transitions, avoiding stress concentration and improving the accuracy and safety of part assembly.

High precision chamfering: chamfering precision parts such as gear tooth roots and thread roots to prevent stress cracking and optimize the surface smoothness of parts (such as Ra1.6-3.2 μ m).

2. Groove processing and engraving

Narrow groove cutting: Processing micro grooves with a width less than 1mm (such as circuit board heat dissipation grooves, mold parting grooves), utilizing the high rigidity and wear resistance of sharp edged blades to ensure consistent groove width and bottom flatness.

Scale and marking processing: Precision scale lines (such as measuring scales, instrument scales) are engraved on the surface of the workpiece, or identification grooves are processed. The sharpness of the blade ensures clear lines and uniform depth (usually 0.1-0.5mm deep).

3. Hole machining assistance

Center hole positioning: Before drilling, machine the center hole (such as a 60 ° center hole) to provide correct positioning for the drill bit and avoid drilling deviation, especially suitable for deep hole machining or high-precision hole systems (such as engine cylinder block holes).

Chamfering of countersunk holes: Chamfering the conical surface of countersunk holes to ensure a tight fit between the screw head and the workpiece surface, commonly used for assembly of sheet metal and box type parts.

4. Mold and special parts processing

Mold engraving: Processing patterns, text, or small structures (such as anti-counterfeiting labels) on the surface of the cavity of plastic molds and die-casting molds, using the high wear resistance of sharp edged knives to maintain long-term processing accuracy.

Edge trimming of irregular parts: Sharpening or blunting the edges of irregular parts such as cams and gears to eliminate machining residual burrs and improve the smoothness of part movement (such as gear meshing efficiency).

3、 Application scenarios

Mechanical processing: automotive parts (such as gearbox gear chamfering), aerospace parts (such as shell narrow groove machining), precision instruments (such as instrument dial markings).Mold manufacturing: chamfering of parting surfaces for injection molds and processing of exhaust grooves for die-casting molds.

Electronic industry: slot cutting of PCB boards, precision etching of semiconductor packaging molds.

Hardware processing: grinding the cutting edges of cutting tools and measuring tools, chamfering the heads of fasteners.

4、 Precautions for use

Cutting parameter control: The heat resistance of high-speed steel is lower than that of ceramic or hard alloy cutting tools. It is recommended to have a cutting speed of ≤ 50m/min and a feed rate of 0.05-0.2mm/r to avoid overheating and wear of the cutting edge caused by high-speed cutting.

Cooling and lubrication: When processing steel parts, emulsion or extreme pressure cutting oil should be used for cooling to prevent chips from sticking to the cutting edge; Dry cutting can be used when processing brittle materials such as cast iron, but debris needs to be cleaned in a timely manner.

Blade maintenance: After the blade is worn, a high-precision grinder (such as a tool grinder) should be used for grinding to maintain a sharp angle error of ≤± 1 ° and avoid affecting the machining accuracy.